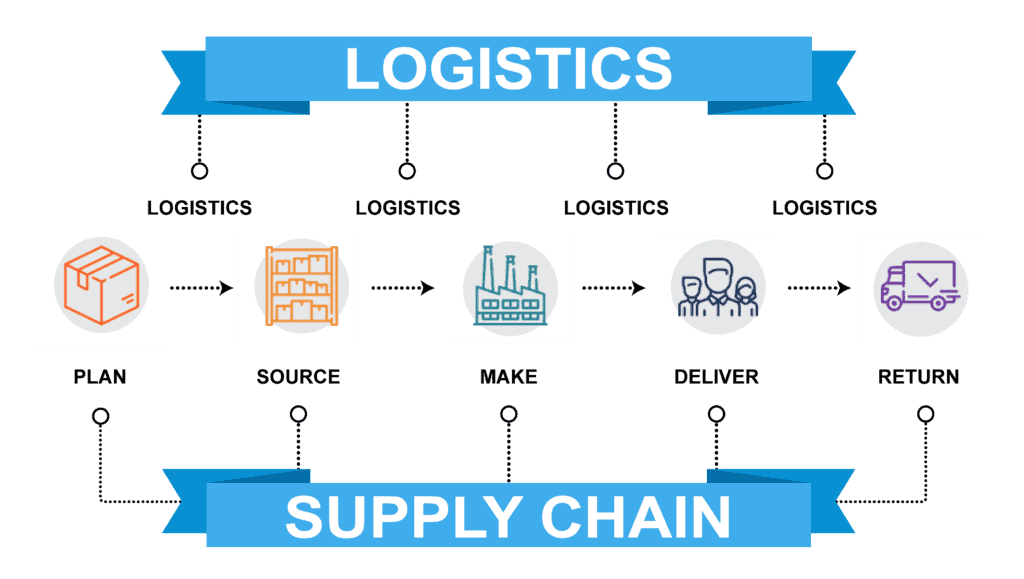

LOGISTICS VS. SUPPLY CHAIN: UNDERSTANDING THE CRITICAL DIFFERENCES AND INTERCONNECTIONS

Introduction

In today’s fast-paced global economy, businesses are under constant pressure to ensure products reach customers efficiently, affordably, and reliably. Two critical concepts that facilitate this process are logistics and supply chain management (SCM). Although the terms are often used interchangeably, they represent distinct yet interconnected functions that govern the flow of goods, from raw materials to final delivery.

To understand this distinction, consider the example of a smartphone manufacturer. Sourcing raw materials, assembling components, and ensuring timely deliveries to retailers all fall under the umbrella of supply chain management. However, specific tasks such as warehousing, inventory control, and last-mile delivery are categorized under logistics.

This article will explore the differences, similarities, and integration of logistics and supply chain management. Understanding these concepts is essential for businesses looking to enhance efficiency, reduce costs, and improve customer satisfaction.

Defining the Terms

To truly grasp the distinction between logistics and supply chain management, it’s essential to define each term and understand their respective roles in business operations.

A. What is Logistics?

Logistics refers to the detailed coordination and management of resources—such as goods, materials, and information—as they move through a supply chain. Its primary goal is to optimize the storage, transportation, and delivery of products to meet customer demands efficiently and cost-effectively.

Key Functions of Logistics:

- Transportation Management: Selecting optimal transport modes (trucks, ships, air freight, rail) and planning efficient routes to reduce costs and delivery time.

- Warehousing & Storage: Storing products in strategic locations to ensure timely distribution.

- Inventory Management: Monitoring stock levels to prevent shortages or overstocking.

- Order Fulfillment: Ensuring accurate picking, packing, and shipping of orders.

- Reverse Logistics: Managing product returns, repairs, or recycling.

Historical Context:

Logistics originated in military operations, where efficient management of supplies was critical to supporting troops. Over time, the concept has evolved and is now integral to business operations, helping companies reduce distribution costs, enhance service levels, and streamline their supply chain.

B. What is Supply Chain Management (SCM)?

Supply chain management is a broader process that encompasses the entire journey of a product, from sourcing raw materials to delivering the final product to consumers. It integrates various business functions—including procurement, manufacturing, logistics, and customer service—into a cohesive and efficient system.

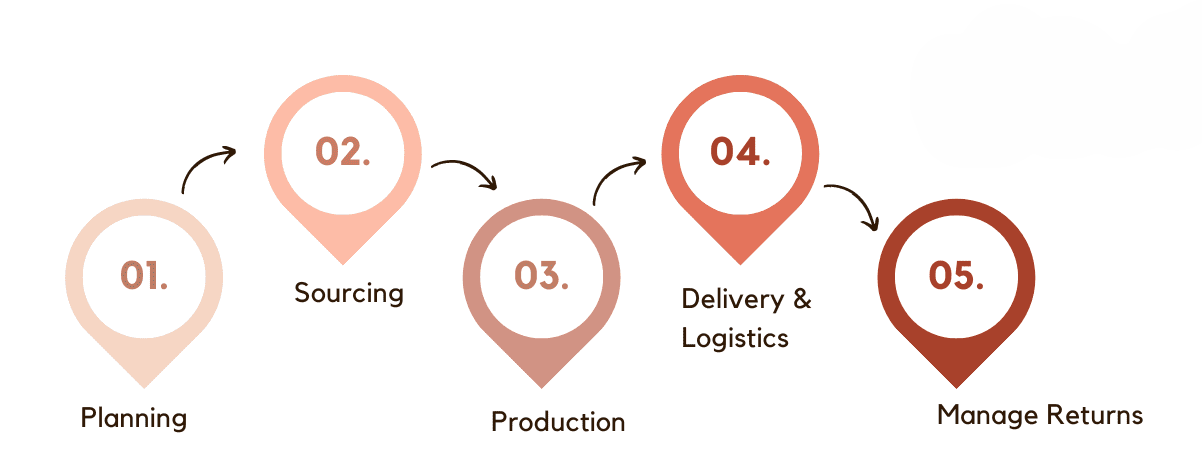

Key Components of Supply Chain Management:

- Procurement & Sourcing: Selecting suppliers, negotiating contracts, and acquiring raw materials.

- Production & Manufacturing: Transforming raw materials into finished products through efficient planning and processes.

- Demand Forecasting & Planning: Predicting customer demand to maintain optimal inventory levels.

- Logistics & Distribution: Coordinating warehousing, transportation, and product delivery (logistics is a subset of SCM).

- Customer Relationship Management: Maintaining high customer satisfaction through efficient service and fulfillment.

- Risk Management & Sustainability: Managing supply chain disruptions and integrating sustainable practices.

How SCM Differs from Logistics:

- SCM is strategic, focusing on decision-making at a high level to ensure all components of the supply chain function harmoniously.

- Logistics is operational, focusing on the execution of day-to-day transportation, warehousing, and inventory management within the larger supply chain strategy.

C. How Logistics and Supply Chain Management Interconnect

While logistics focuses on the movement and storage of goods, SCM ensures that the entire product journey—from sourcing to final delivery—is optimized.

Think of it this way: logistics operates like the gears in a machine, ensuring smooth functioning, while SCM is the blueprint that organizes how those gears work efficiently.

Comparing Logistics and Supply Chain Management

Though closely related, logistics and supply chain management differ in several critical aspects, including scope, objectives, and functions.

A. Scope and Focus

- Logistics: Concerned primarily with the movement, storage, and flow of goods within a distribution network. Its primary objective is to improve efficiency and reduce costs related to transportation, warehousing, and order fulfillment.

- Supply Chain Management (SCM): Encompasses the entire network, including suppliers, manufacturers, distributors, and retailers. It aims to optimize the flow of materials, finances, and information, making strategic decisions that affect procurement, production, and distribution.

Example: A retail company’s logistics department ensures that products are stored in the correct warehouse and shipped efficiently. Meanwhile, the supply chain department manages supplier relationships, negotiates contracts, and ensures that production meets customer demand.

B. Objectives

Logistics:

- Ensure timely and cost-effective delivery of goods.

- Optimize transportation, warehousing, and inventory management.

- Minimize operational costs.

- Improve order accuracy and customer satisfaction.

Supply Chain Management:

- Enhance overall business efficiency through coordination among suppliers, manufacturers, and distributors.

- Strengthen supplier relationships and improve procurement processes.

- Reduce risks and disruptions within the supply chain.

- Leverage technology and data for informed decision-making.

C. Key Differences

| Feature | Logistics | Supply Chain Management |

|---|---|---|

| Definition | Focuses on transporting and storing goods. | Encompasses sourcing, production, and delivery management. |

| Focus | Movement, storage, and distribution. | End-to-end product lifecycle and business strategy. |

| Key Processes | Warehousing, transportation, inventory management, order fulfillment, reverse logistics. | Procurement, production, logistics, demand forecasting, risk management. |

| Timeframe | Short-term, operational focus. | Long-term, strategic planning focus. |

| Objective | Efficient delivery and storage of goods. | Optimized coordination of the entire supply network. |

| Technology Used | Warehouse Management Systems (WMS), Transportation Management Systems (TMS). | Enterprise Resource Planning (ERP), Supply Chain Management Systems (SCMS). |

| Example | Managing a fleet of trucks for product distribution. | Managing supplier relationships and production schedules. |

D. How Logistics and Supply Chain Management Work Together

Logistics and supply chain management must collaborate seamlessly for a business to succeed.

- SCM sets the strategy: This involves determining material sources, production organization, and distribution channels.

- Logistics executes the plan: Ensures goods are transported, stored, and delivered efficiently based on the supply chain strategy.

Example in E-Commerce:

- SCM: A company like Amazon sources products from global suppliers, negotiates contracts, and coordinates manufacturing.

- Logistics: Amazon’s logistics team handles warehousing, shipping, and last-mile delivery to customers.

E. The Role of Technology in Both Fields

Advancements in artificial intelligence (AI), the Internet of Things (IoT), and automation are revolutionizing logistics and supply chain management. Some of the key technologies include:

- IoT & RFID: Enable real-time tracking of shipments.

- AI & Predictive Analytics: Aid in demand forecasting and optimizing transportation routes.

- Blockchain: Enhances transaction transparency and security.

- Robotics & Automation: Speed up warehouse operations, improving order fulfillment efficiency.

Conclusion

While logistics and supply chain management have distinct roles, they are highly interdependent and must work together for optimal business performance. A failure to integrate these functions effectively can lead to operational inefficiencies, increased costs, and customer dissatisfaction. As technology continues to evolve, the collaboration between logistics and SCM will become even more integral to maintaining a competitive edge in the market.

By understanding and optimizing both logistics and supply chain management, businesses can streamline operations, reduce costs, and enhance customer satisfaction, ultimately improving their bottom line in today’s competitive global market.